Material thickness

- General: 0.003 - 1.5 mm.

- Titanium standard up to and including 0.5 mm.

- Other thicknesses are available on consultation.

Dimensions

- Standard up to gross 550 x 550 mm.

- Large parts:

- Gross ≤ 2000 x ≤ 625 mm

- Thickness ≤ 0.5 mm

Tolerances

- Standard +/- 10% of the material thickness with a minimum of +/- 0.01 mm.

This can however vary depending on the material and configuration.

- Special hole tolerances, for example H7, are etched as standard on undersize so that they can be reamed to size.

- We always use nominal dimensions as a starting point.

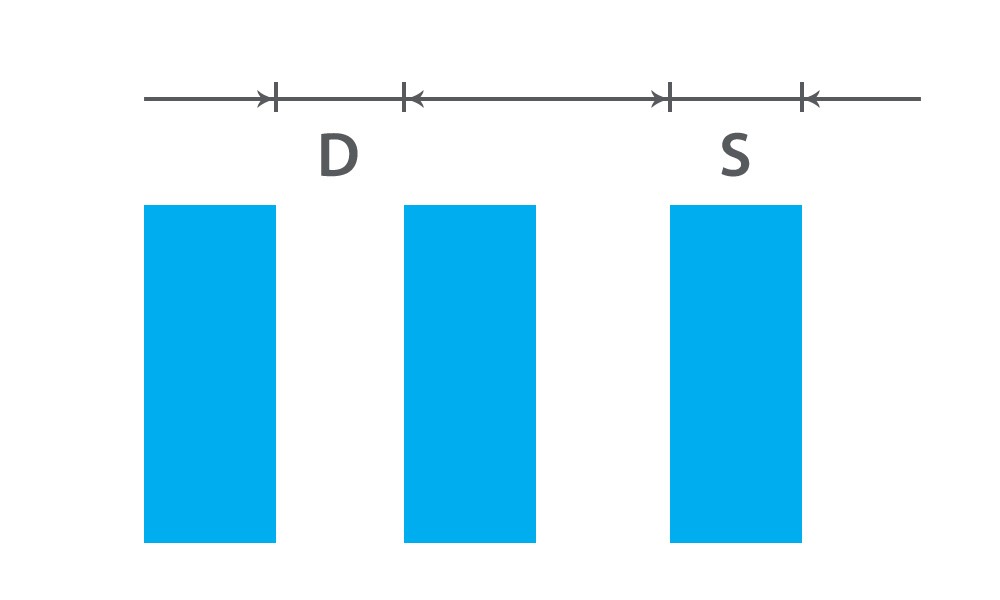

Dam and slot width

| |

D = dam |

G = slot/hole |

|

| iron, carbon steel, stainless steel etc. |

1 T |

1,2 T |

| nickel |

1,25 T |

1,5 T |

| copper, bronze, brass, beryllium copper etc. |

0,8 T |

1,1 T |

| Gold |

1,5 T |

2 T |

| Aluminium |

1,3 T |

1,5 T |

| molybdenum, silver |

0,8 T |

1,1 T |

| Titanium |

1,25 T |

1,5 T |

The minimum feasible dam and slot width is largely determined by the material thickness as follows:

| |

D = dam |

G = slot/hole |

| < 0,1 mm |

1,2 T |

1,2 T |

| 0,1 - 0,2 mm |

0,1 mm |

1,1 T |

| > 0,2 mm |

0,15 mm |

1 T |

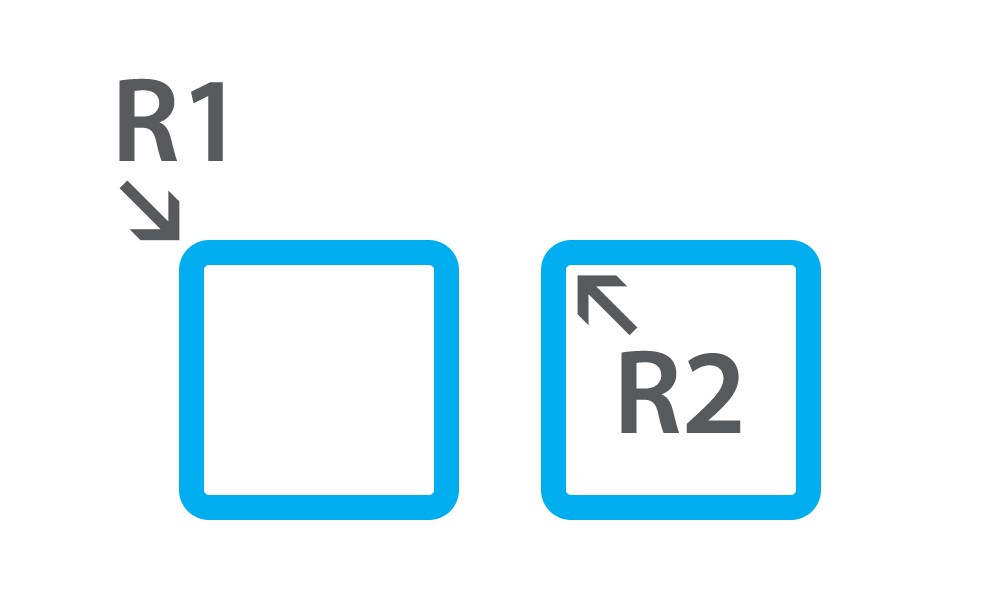

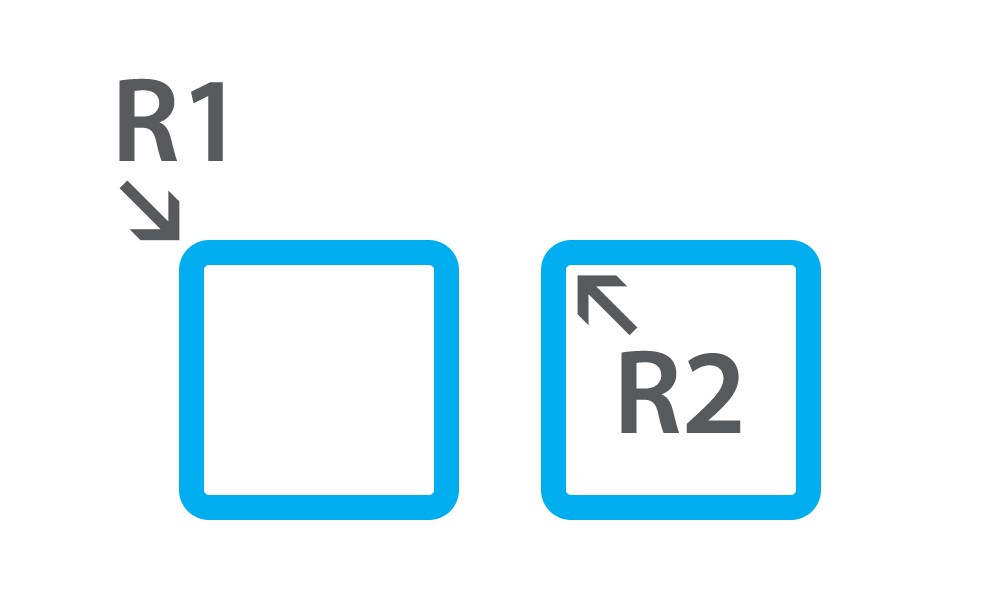

Internal and external corner radius

| |

R1 |

R2 |

|

| < 0,1 mm |

≥ 0,75 T |

≥ 1 T |

| 0,1 - 0,2 mm |

≥ 0,75 T |

≥ 1 T |

| > 0,2 mm |

≥ 0,75 T |

≥ 1 T |

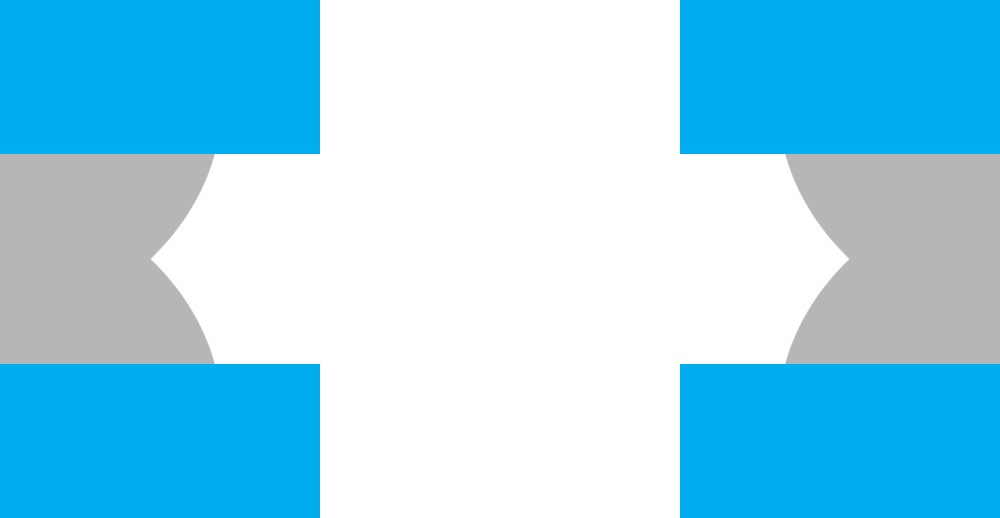

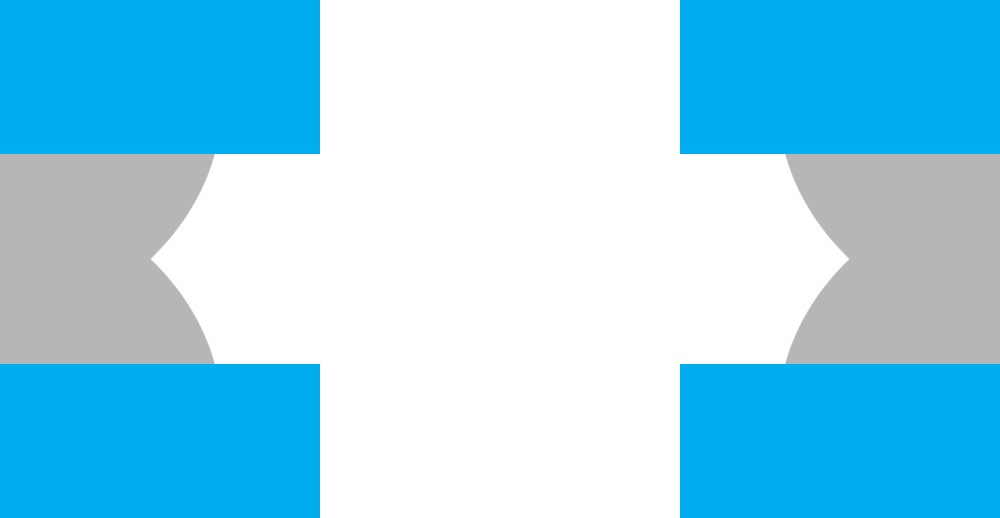

Etching profiles

|

|

|

|

|

| biconvex |

biconcave |

depth etching |

convex |

spits |

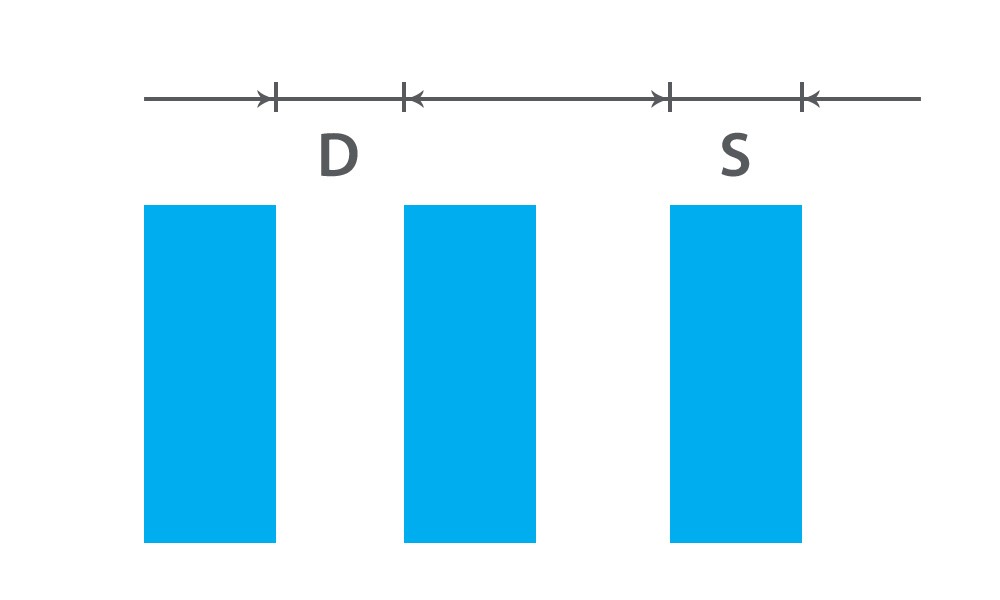

Connection tabs

- Etching takes place in sheets in which products can be configured both separately and with connection tabs.

- It is preferable to etch with connection tabs: this is more efficient and gives a higher dimensional accuracy. Here you can choose between connecting and recessed connection tabs.

- In addition, etching can take place separately if connection tabs are not an option. This is more laborious and gives a somewhat larger tolerance field.